Your car’s electrical system is a complex network, much like the nervous system of the vehicle, ensuring power flows where it’s needed to make everything from your headlights to your engine run smoothly. At the heart of this system are three fundamental components: car wires, automotive connectors, and car wire harnesses. But understanding when you need one versus the other can be confusing. Do you just need a simple wire? Is a connector the solution? Or does your entire harness need replacing? This guide breaks down each component, their uses, and how to determine which one you actually need for your vehicle’s electrical health.

Knowing the difference isn’t just about DIY repairs; it’s about understanding your vehicle better, ensuring safety, and avoiding costly mistakes. Whether you’re dealing with a flickering light, a dead accessory, or planning an upgrade like adding a new stereo system, identifying the correct electrical component is the first step. Let’s dive into the world of automotive wiring to demystify these essential parts.

Car wires, often referred to as cables in some contexts, are the foundational elements of any electrical system. They are essentially conductors, typically made of copper or aluminum, designed to carry electrical current from one point to another within your vehicle. These wires are insulated with various materials like PVC, Teflon, or silicone to protect the conductor from physical damage, environmental factors like moisture and heat, and to prevent short circuits by keeping adjacent wires separated.

The gauge, or thickness, of a car wire is critical and is usually measured by an American Wire Gauge (AWG) number. A lower AWG number indicates a thicker wire, which can carry more current without overheating. For instance, a thick gauge wire might be used for the main power feed to the starter motor, requiring substantial current, while a much thinner gauge wire could be sufficient for a small interior light. Using the wrong gauge wire can lead to serious problems: a wire too thin for the current load will overheat, potentially melting insulation, damaging the automotive connector it’s attached to, or even causing a fire. Conversely, using a wire significantly thicker than necessary is often unnecessary and can make routing difficult and add unnecessary weight and cost.

Wires in vehicles are subjected to harsh conditions – vibration, temperature extremes, exposure to oils and chemicals, and physical abrasion from moving parts or sharp edges. Over time, this can lead to insulation degradation, fraying, or even breaks in the conductor itself. Common signs of wire issues include visible damage to the insulation, exposed copper strands, or wires that feel brittle or cracked. Electrical symptoms like intermittent power loss, flickering lights, or accessories that don’t function properly can also point to underlying wire problems.

When you need a replacement, it’s not just about getting any wire. You need the correct gauge, the appropriate insulation type for the application (e.g., high-temperature insulation near the engine), and sometimes specific colors or lengths to match the original or fit the repair. While sometimes a single wire replacement is sufficient, often wire issues are part of a larger problem involving the automotive connector or the entire car wire harness it’s integrated into. Understanding the specific application is key to selecting the right wire.

Automotive connectors are the critical junction points in your vehicle’s electrical system. Think of them as the hands that join the arms (wires) together or connect them to a component. Their primary function is to establish a secure, reliable electrical connection between two or more wires, or between a wire and a device like a sensor, light, or switch. Without these connectors, routing individual wires throughout the vehicle would be an impossibly complex and unreliable task.

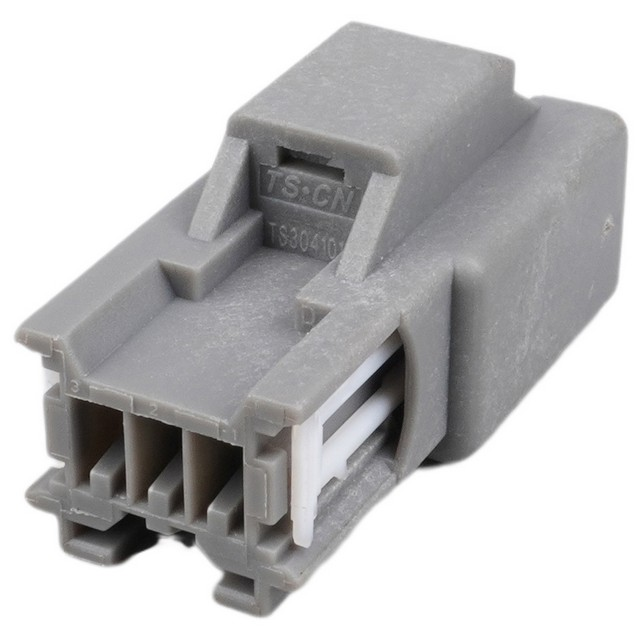

Connectors come in a staggering variety of shapes, sizes, and designs, tailored for specific applications and environments. Some are simple, two-pin connectors for low-current signals, while others are large, multi-pin units handling significant power for components like headlights or electric motors. They are typically made of plastic (for the housing) and metal (for the contacts). The housing protects the contacts and often includes features like locking mechanisms (latches, tabs, screws) to prevent accidental disconnection due to vibration or movement. The contacts are designed to grip the wire terminals firmly, ensuring a low-resistance path for current flow.

The reliability of an automotive connector is paramount. A poor connection can cause intermittent failures, increased resistance leading to overheating, or complete loss of function for the connected component. Common issues include corrosion (especially in humid or salty environments), damaged or bent pins, melted housings (often due to overheating or proximity to heat sources), or worn-out locking mechanisms that allow the connector to come loose. Symptoms of connector problems mirror those of wire issues – flickering lights, dead accessories, sensors not working, or erratic electronic behavior.

Selecting the correct automotive connector is crucial. Factors to consider include the number of pins required, the current rating (must handle the load without overheating), the wire gauge it’s designed to terminate, the environmental conditions it will face (waterproofing, temperature resistance), and the specific locking mechanism needed to ensure it stays connected. Using an incompatible connector can lead to poor electrical contact, accelerated wear, and potential system failure. In many cases, when a connector fails, it’s not just the connector itself that needs replacement but also the section of the car wire harness it’s integrated into, as the wires leading to it may also be damaged or incompatible with a standalone connector.

A car wire harness, sometimes called a wiring loom or cable assembly, is essentially a pre-assembled bundle of wires and automotive connectors. It’s designed to route electrical power and signals from the vehicle’s power source (like the battery and alternator) to various components throughout the car, and to link those components together. Think of it as the central nervous system of your vehicle’s electrical architecture, neatly organizing and protecting the complex network of wires needed to operate everything from the engine control unit (ECU) to the radio and power windows.

Manufacturers design specific car wire harnesses for each model and year of vehicle. These harnesses are carefully engineered to fit the unique layout of the car, routing wires through precise channels, around obstacles, and connecting to the correct components using the appropriate automotive connectors. They often include protective sleeving, conduit, or even conduit-like structures (loom) to shield the wires from physical damage, abrasion, heat, and environmental contaminants. Harnesses can range from simple, short bundles for a single component to massive, complex assemblies running the entire length of the vehicle, integrating dozens or even hundreds of wires and connectors.

The primary advantage of a car wire harness is organization and reliability. It simplifies installation by providing a pre-wired solution, reduces the chance of wiring errors, minimizes wire clutter, and protects the delicate wires from the harsh automotive environment. However, because they are integral to so many systems, a fault in a car wire harness can cause widespread electrical problems. Common issues include chafed insulation leading to short circuits, broken wires (often hidden deep within the bundle), failed or corroded automotive connectors integrated into the harness, or damage from accidents, heat, or rodents chewing through the protective sleeving.

Diagnosing a problem within a car wire harness can be challenging. Symptoms can be vague and affect multiple unrelated systems. For example, a short circuit in a harness near the engine might cause the engine to stall, the radio to cut out, and the interior lights to flicker simultaneously. Repairing a harness can sometimes be done by splicing in new sections of wire or replacing faulty connectors, but often, especially if the damage is extensive or in a difficult-to-reach location, replacing the entire car wire harness is the most practical and reliable solution. This is often the case when dealing with age-related degradation or significant impact damage.

Identifying that you need a replacement car wire, automotive connector, or car wire harness is only half the battle. The next step is acquiring the correct part. Traditionally, this meant visiting a dealership parts counter or an auto parts store, potentially facing limited stock, long wait times for special orders, or paying premium prices. However, the landscape has changed dramatically.

Today, you can easily source almost any replacement electrical component for your vehicle from the comfort of your home. Online auto parts retailers offer vast inventories, detailed part information, and sophisticated search tools. You can typically enter your vehicle’s year, make, model, and sometimes even the engine type or trim level, and the website will filter the results to show only parts guaranteed to fit your specific vehicle. This significantly reduces the risk of ordering the wrong part.

When searching online for replacements, pay close attention to the specifications. For car wires, note the gauge, length, and insulation type. For automotive connectors, look at the number of pins, the type of contacts (spade, blade, pin, etc.), the housing style, and any specific locking mechanisms. For car wire harnesses, ensure you’re selecting the correct part number for your vehicle’s exact configuration. Many reputable online retailers also provide detailed product descriptions, images, and sometimes even application notes or fitment guides to help you make the right choice.

Websites like TSCN Connector (https://www.tscnconnector.com/) specialize in providing high-quality electrical components, including a wide range of automotive connectors and related wiring solutions. They often offer detailed product information, allowing you to compare specifications and choose parts that meet your exact requirements. Ordering online often comes with benefits like competitive pricing, fast shipping options, and the convenience of having the part delivered directly to your doorstep. This ease of access empowers DIY mechanics and professional technicians alike, making vehicle electrical maintenance and repair more efficient and cost-effective.

Furthermore, online platforms frequently allow you to read reviews from other customers who have purchased and used the parts, providing valuable real-world feedback on quality and performance. Some sites even offer technical support or forums where you can ask questions if you’re unsure about a specific part. This wealth of information and convenience makes sourcing replacement car wires, automotive connectors, and car wire harnesses without leaving your home not just possible, but often the preferred method.

In conclusion, understanding the distinct roles of car wires, automotive connectors, and car wire harnesses is fundamental to maintaining your vehicle’s electrical health. While wires are the conductors, automotive connectors are the critical junctions, and harnesses are the organized systems that bring it all together. Knowing which component you need – whether it’s a simple wire splice, a specific connector replacement, or a complete harness overhaul – depends on accurately diagnosing the problem and understanding your vehicle’s electrical architecture. Thankfully, the ability to easily research and purchase these parts online, from sources offering detailed specifications and competitive pricing like specialized providers, has made tackling these repairs more accessible than ever. By making informed choices and sourcing quality components, you can ensure the reliable operation of your vehicle’s essential electrical systems.

يستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.

تعليق

(0)